AHC Seeks Program Partnerships with New Niche

Date: September, 2022

Mableton, GA–Atlanta Hardwood Corporation (AHC) is headquartered here, just outside of Atlanta. Founded in 1952 as Howard Lumber & Kilns by James W. Howard, Sr., the company has evolved over the years, by introducing industry-leading technology and production techniques to address the needs of the ever-changing manufacturing and construction markets.

With decades of success in the hardwood forest products industry, AHC has recently entered the Softwood side of the industry, bringing with them a thriving niche market. The company inventories approximately 16 million board feet. Three million of which, President Hal Mitchell said, is Softwoods including Yellow Pine and White Pine. “Historically, we have always processed hardwoods,” he explained. “Many of our hardwood sawmill partners are now manufacturing Softwoods which has provided us an opportunity to kiln-dry Pine and process it through our moulding plants into boards or profiled mouldings to service millwork distributors in new market sectors.”

He continued, “We saw an opportunity to develop custom millwork as an available resource. When we noticed our sawmill base was basically being forced to cut a percentage of Softwoods, we recognized there was an opportunity for us to develop manufacturing procedures to get the Softwoods processed and dried correctly. The result of which would provide a new market in the residential sector. For us it was a real opportunity because few companies can offer these products on a commercial scale.”

Explaining the process, Mitchell offered, “Starting with green lumber, we can dry and remanufacture boards into pattern stock from virtually any species including several Softwoods: White Pine, Southern Yellow Pine, Aromatic Cedar, and Cypress, along with our traditional hardwood product lines. We are handling strictly those four species in Softwoods. We can process the upper grades as well as No. 2 common, and we dry it a little bit differently. Most large Yellow Pine mills will dry for construction moisture content. By utilizing our hardwood kilns, we can fully set the sap and produce a finished product that is excellent for interior use with an 8 to 10 percent moisture content. That is our new niche in the market, and it’s a different approach to the Softwood markets.”

With 175 sawmill partners overall, Mitchell said about 20 of these are Softwood supplier sawmills. “For us, it was a way to help our sawmills merchandise their production. They were often new to cutting Yellow and White Pine, so it was a way for us to help in supply chain management. Most of the Softwood that we are processing is being machined into paneling products, mouldings, and trim. They can now merchandise the higher grades to us for the millwork industry and can continue to sell their low grades to their treaters or construction-based manufacturing” he explained.

With AHC’s tripling of their production capacity with the addition of a new millwork facility in Clarksville, TN and upgrades at the Cleveland, GA plant, AHC is actively seeking partnerships for value-added markets. Mitchell explained, “We’re making ourselves available and seeking supply partners that have boots on the ground and active sales forces in the wholesale distribution industry that can go out and market these products. We are looking for long-term partnerships with stocking distributors that can take these products to market.”

As for the new millwork facility in Clarksville, Mitchell said, “We purchased the Clarksville, TN facility which was previously the Averitt Lumber Company in 2008. Initially, we ran the plant as a hardwood concentration yard catering to the export market, supplying poplar, red and white oak, and ash. Over the years, our vision has evolved toward more value-added markets. Further vertical integration helps us control the supply chain and quality from green lumber all the way through to the finished products.”

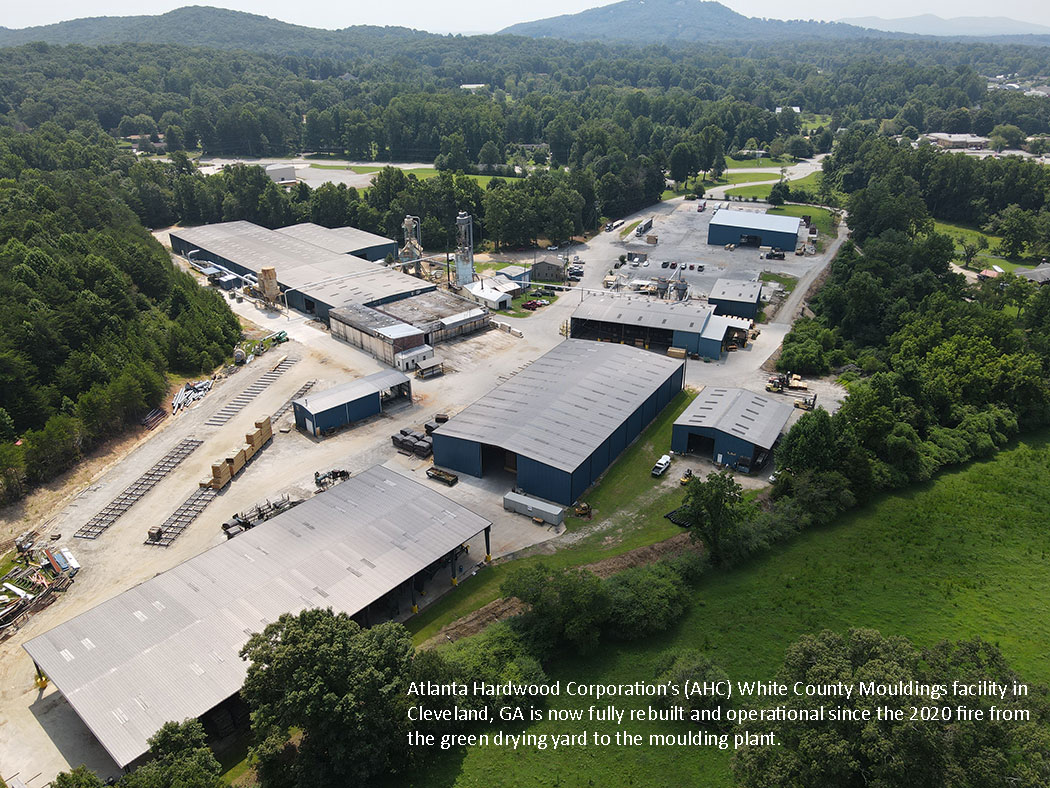

Today, AHC purchases 65 percent green lumber and 35 percent kiln-dried lumber, including some import species. Mitchell noted the success of AHC’s White County Moulding facility provided the groundwork that led to the value-added expansion at Clarksville. “We had a massive fire in October of 2020 at our moulding plant in Cleveland, GA. We had just begun installation on the new moulding facility in Clarksville, TN, with a five-year anticipated build out. We were able to fast track the TN facility while rebuilding our GA plant to have both facilities become fully operational within a year. We designed the plants to process both random width and dimensional lumber for both Softwood and hardwoods. Our moulders are unique in that they are high-speed, 8-head machines. We can efficiently process the Softwood products and dimensional hardwood products through our equipment. We also installed WoodEye scanners and Eagle rip and chop systems so that we can scan for defects, optimize yields, and provide cut-to-length component parts for large scale production.”

According to Mitchell, “Today our north Georgia facility has a smaller footprint, but has successfully incorporated a lean manufacturing culture. The equipment is more automated which allows us to reduce our labor and increase volume. It was a win so we duplicated the process at our plant in Clarksville. Historically, we produced architectural mouldings and S4S profiles. With the new WoodEye scanning defect lines, we can supply finished component parts in blank or moulding form. Whether we are chopping the blanks to precision length prior to moulding or after moulding, we have the capability to do both functions at any of our reman facilities.

“Our mission,” Mitchell stated, “is to become a world-class, value-added manufacturer of lumber and mouldings. We are developing a LEAN culture and servant leadership where our management group supports our employees to become more actively engaged, giving them ownership in their daily production. Whether the plant is winning or losing on a particular day, we want everyone to understand that we are part of a team, working toward the same goals. Our focus is controlling the process from the green mill all the way through to the stocking distributor level. Our regional distributors have the sales teams and logistics tools to service local customers. We supply them with both a competitive cost and production efficiency savings for an array of value-added wood products or kiln-dried lumber to service their customer base.”

Repeat business has driven AHC’s long-term success. Mitchell said, “Our investments are driven by our customers’ requests to help resolve some of their labor and supply challenges. We’re striving to meet their needs. We can often optimize the raw material and provide a natural, lower-cost solution for them than as compared to what they could produce in-house. We serve millwork manufacturers, OEMs, and two-step distributors that sell to retail outlets. We focus on our customers’ needs to supply them with value-added alternatives to help solve their production and personnel constraints.”

At White County Mouldings, Mitchell said the operation leans heavily to high grade lumber from a secondary manufacturing standpoint. “Everything that goes through the production plant is typically No. 1 common and better, 4/4 through 8/4 thicknesses,” he explained.

Mitchell continued, “Our hardwood domestic species mix is heavy poplar, red oak, hard and soft maple, ash, cherry, and walnut. We are direct importers of a variety of exotic and tropical species, such as red grandis and sapele. Whatever fits our customers’ needs, we can leverage our supply partners to provide consistent program-style business. We’re collaborative partners with our vendors and our customers, and rely heavily on feedback from both. Our objective is to help them manage their businesses more effectively.”

On the logistics side, Mitchell said, “We have repositioned and added some additional trucks at our Clarksville, TN and Cleveland, GA facilities. We’ve always shipped volume lumber and now our fleet has been expanded to ship value-added products. AHC has been able to maintain our lumber supply channels while increasing our volume mix in value-added products.” With 16 company-owned trucks, AHC Logistics is the right arm of the AHC operation. Mitchell explained, “Since we operate our own fleet, we can mix products on a single truck to include units of rough or surfaced and ripped lumber in domestic or imports, ripped blanks, all the way down to moulding and millwork products, like S4S and paneling, and consolidate shipments to send to a stocking distributor. This allows our customers to control purchasing for better management of their inventory and turns.

“We run our own fleet within a 1,000-mile radius of our manufacturing plants in the southeast and we ship to other locations through either use of a common carrier, containers, or box van – whatever works best for the customer. We have loading facilities at all our plants that can handle anything from flat beds to hot shot trailers and LTLs, all the way through the box van and van loading to containers.” Typical turnaround time for delivery of dimension products is two to three weeks. AHC takes extensive measures to protect its products, including curtain-side trailers, cardboard covers, stretch wrapping, airbags, and runners or skids.

Special requests are common for AHC, which Mitchell said they are prepared to accommodate. “All of our facilities have multiple 12-inch moulders to meet customer demands. Our automated scanning equipment has 12-inch chop lines in place to help facilitate the S4S and specialty programs with 1/16-inch length tolerances. We have defect saws that are capable of chopping 6x12s or 8x8s for more industrial-type applications through the system. We also do all tooling in-house from CAD drawings to knife making.”

Serving the furniture and cabinet industries for years, AHC is now also doing business on the industrial side. Mitchell added, “We still have a diverse product offering in dimensional components, from small component parts to large industrial sizes. We manufacture hobby board programs that are from ¼ inch by 1-½ inch, all the way up to a large 2-inch by 11-¼ inch S4S program.”

Celebrating its 70th anniversary this year, AHC began as a lumber brokerage business. The elder Mr. Howard, father of the current chief executive officer, Jim Howard, grew his business by selling to furniture manufacturers in eastern Tennessee and western North Carolina. In the mid-1950s, the company was moved to Atlanta and began processing Appalachian hardwoods in leased kilns. By 1960, a plant was built in Mableton, GA. In 1966, a second plant in Huntersville, NC was opened to service the furniture industry in the Carolinas.

Under the leadership of the younger Howard, the company has grown to include three drying yards operating as AHC Hardwood Group. Also operating under the AHC brand are the AHC White County Mouldings plant in north Georgia, AHC Import Lumber, importing African and South American hardwoods, AHC Export Lumber, which sells Appalachian hardwoods around the world, and AHC Logistics, the trucking division of the company.

As a multi-generational company with a long-term vested interest in sustainable forestry, AHC Hardwood Group is committed to renewable wood resources and responsible forest stewardship. AHC is a member of the North American Wholesale Lumberman’s Association, National Hardwood Lumber Association, the Hardwood Manufacturers Association, the Southern Cypress Manufacturers Association, the Indiana Hardwood Lumbermen’s Association, and the Kentucky Forest Industries Association. For more information, visit www.hardwoodweb.com.

.svg)